Mounting gas springs

Does it matter in which place I mount the hinges?

It is best to place a hinge as much as possible in line with each mounted gas spring. The reaction force, coming from the gas spring, can be led through the hinge to any non moving part .

Not placing a hinge in line with the gas spring, calls on the local strength of the cover or the hatch to lead the reaction force, via a transverse movement, still through the hinge to the mounting point. When the cover or the hatch has sufficient stiffness that is not a problem, but when the edge of the cover or the hatch has been structured as a frame, this issue demands attention.

In order to prevent uneven loads on the hinges, it is desirable to place the hinges symmetrically to the mounted gas springs.

How do I reduce excessive force on the pivot point of my cover or hatch?

The reason for this conclusion can be that:

- the hinges are not strong enough to lead this force to the non moving part.

- that the hinges cannot be sufficiently firmly attached to the cover, the hatch or to the non moving part.

- that the cover or the hatch itself, is not strong enough constructively at the location of the hinges.

When placing the hinges it is good to keep the following in mind:

- Number of hinges = number of gas springs with a minimum of 2 pieces.

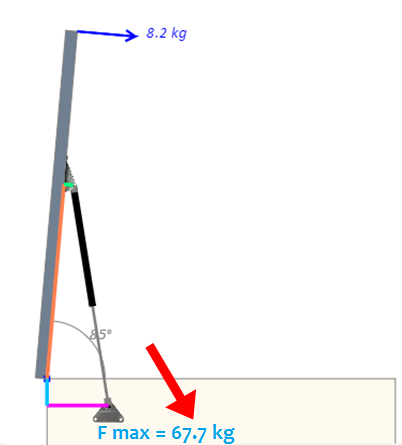

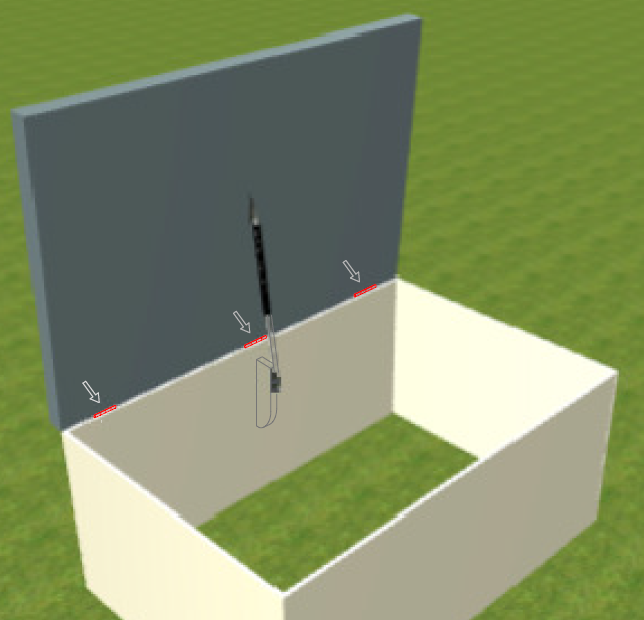

- However, when one gas strut is used, then use 3 hinges: the middle hinge halfway the width of the cover and mount the gas spring, aligned with the middle hinge (see example below)

In general, therefore, the following applies: Attach a hinge as well as possible in line with each gas spring.

When this condition is met, then the load (force) per hinge is equal to the force at the pivot point divided by the number of gas struts.

This means that when we apply one gas spring, the whole force at the pivot point of the cover given by the Calculation tool, must be able to be led through one hinge to the non moving part.

If, however, we mount one gas strut halfway the width of the cover, without a 3rd hinge right behind the gas spring, then the force at the pivot point of the cover given by the Calculation tool will, nevertheless, be divided over two hinges but then the stiffness of the cover is required to lead that force to the left and to the right towards the hinges. A disadvantage here, because of the lack of the 3rd hinge, is that the cover at the location of the middle-mounted gas struts may bulge, because the gas spring continues to exert a constant pressure on the cover when the cover is closed. Especially with a wooden cover this bulge will, in the course of time, be explicitly visible (wood simply bends).

A question that can be asked afterwards is the following: “Does it make sense to mount, for example, 4 hinges whilst I am only going to apply two gas springs?”

Answer: That definitely makes sense but the hinges that are placed right behind the gas struts jointly transfer the force at the pivot point of the cover, given by the Calculation tool, to the non moving part.

When all the above are met and the load per hinge is still considered too high, what can still be done to reduce the force per loaded hinge?

Answers:

- Select a gas strut with a longer stroke in the outcome of the Calculation tool. That gas spring will be mounted further from the pivot point of the cover and will therefore also need to be less forceful so that the total reaction force at the pivot point of the cover will be lower.

- Mount more robust hinges. This is not always possible because the hinges in terms of size have to continue to be in proportion to the dimensions of the cover. Therefore, it may be considered to place two hinges per loaded hinge position that then should be mounted next to each other stiffly. This halves the load per hinge and also doubles the number of screws